Drywall vs Composite Safes: Which Offers Real Protection?

Think Your Safe Is Secure? The Inside Might Say Otherwise

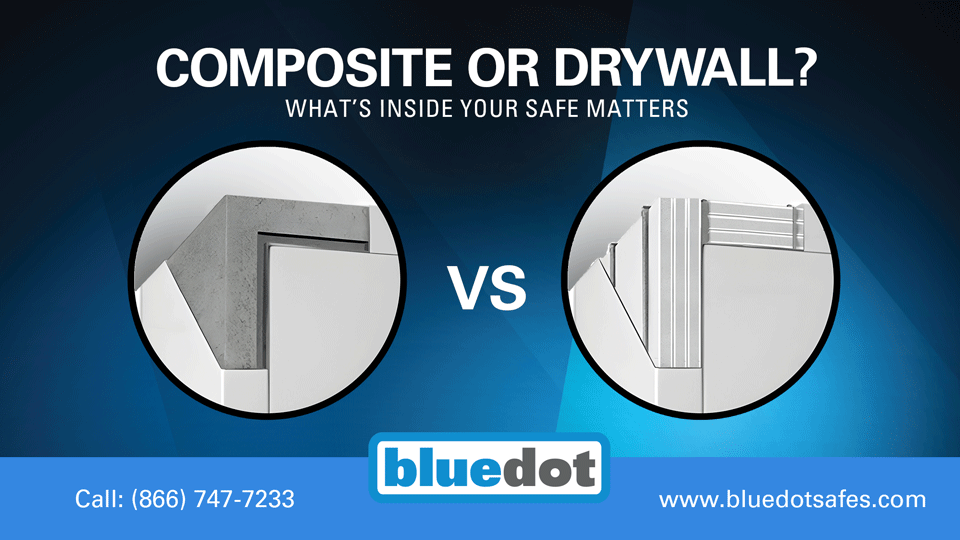

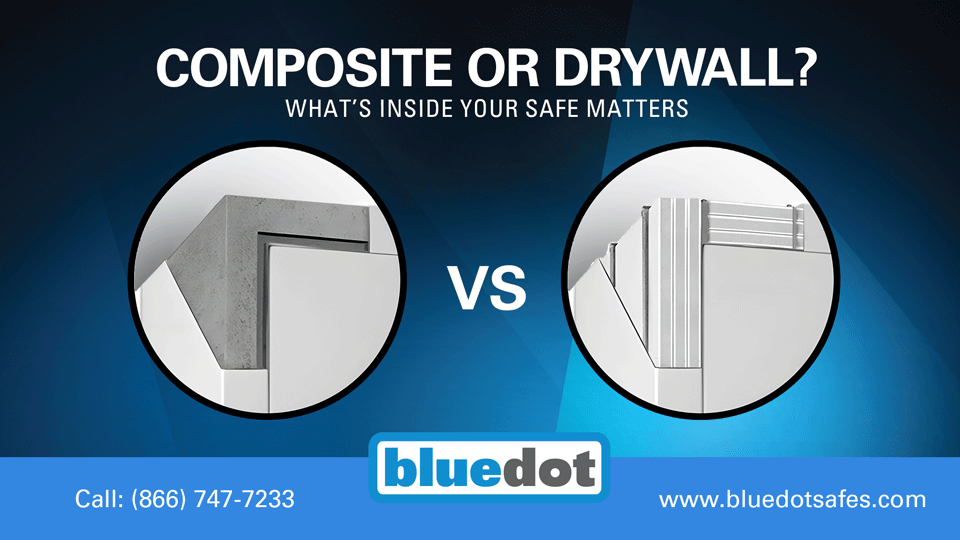

🔐 What’s Inside Your Safe Matters: Composite vs Drywall

When most people shop for a safe, they often prioritize fire ratings, price, and appearance. But what lies inside the walls of that safe—the core insulation and structural build—can make all the difference in a real emergency.

Two of the most common internal constructions are drywall-based insulation and composite materials. Although they may look similar from the outside, their internal build quality determines how well they protect your valuables from fire, burglary, and long-term degradation.

🧱 The Two Main Types of Safe Construction

1️⃣ Drywall-Based Fire Insulation

Drywall (gypsum board) is widely used in entry-level safes for fire resistance. It’s affordable and relatively easy to install.

However, there are several drawbacks:

- Adhesive failure: Often glued or taped, drywall can detach during high temperatures.

- No burglary protection : It offers minimal resistance to physical attack.

- Moisture risks: Post-fire, drywall can break down, become brittle, and even introduce moisture into the safe’s interior.

Note : While drywall-based safes may pass fire tests, their protection often degrades quickly in real-world scenarios involving extreme heat, humidity, or impact.

2️⃣ Composite Construction

Composite safes use a dense blend of concrete, ceramic, and proprietary fire-resistant materials, encased between thick steel plates.

Key advantages:

- Dual protection against fire and forced entry.

- Won’t crumble under high temperatures or stress.

- UL TL-rated burglary certifications (TL-15, TL-30, TL-30X6), meaning tested resistance to tool attacks

These safes are heavier and more expensive but deliver superior performance and durability, especially in commercial or high-risk environments.

🔥 Fire Ratings Aren’t Created Equal

Fire ratings can be misleading. Many safes display a “1-hour fire rating,” but the testing method matters:

- In-house testing by some brands lacks third-party validation.

- UL-tested composite safes adhere to industry-recognized standards.

- Drywall safes may stack multiple boards to fake performance—without increasing true fire resistance.

🔩 Reinforcement: Doors, Hinges & Locking Mechanisms

Burglars often target the door and hinges, not just the walls. Composite safes typically feature:

- Thicker boltwork with anti-pry bars.

- Internal relockers that activate when tampered with.

- Fully welded steel reinforcement at critical entry points.

In contrast, many drywall safes use thin sheeting with no structural backing, making them vulnerable to break-ins.

🌫️ Humidity, Rust & Long-Term Storage

Few realize drywall can:

- Hold moisture or release chemicals (like formaldehyde).

- Corrode firearms, electronics, and metals.

- Cause mold in humid environments.

Composite insulation is chemically stable and safer for long-term storage.

🔧 TL-Rated Burglary Resistance: What It Means

UL’s TL (Tool-Resistant) ratings are the gold standard:

- TL-15: Resists sophisticated tools for 15 minutes.

- TL-30: Resists advanced tool attacks for 30 minutes.

- TL-30×6: Resists advanced tool attacks for 30 minutes on all 6 sides.

Drywall safes are ineligible for these ratings due to their soft, non-resistant cores. Composite safes pass because they’re built with multi-layer steel and reinforced concrete.

🛠️ Maintenance & Serviceability

Over time, safes need inspections, repairs, or upgrades.

Composite advantages:

- Remain structurally sound even after fire.

- Often modular and serviceable.

- Eligible for professional maintenance plans (like locksmith access or bolt replacement).

Drywall units often need total replacement after damage.

🧠 Store What Matters, Store It Right

The safe you choose should match what you’re protecting:

- Paperwork vs. Jewelry vs. Firearms.

- Fire risk vs. Break-in risk.

- Dry garage vs. Controlled office.

Composite safes are made for high-risk, high-value environments—and won’t degrade when you need them most.

🌱 Environmental & Ethical Considerations

- Made-in-USA composite safes follow stricter quality and environmental standards.

- Imported drywall materials may contain inconsistent chemicals and lack oversight.

- U.S. brands support local jobs, ethical sourcing, and long-term reliability.

🏪 Why Smart Retailers Choose Composite Safes Over Drywall

✅ Lessons from Blue Dot’s Build Philosophy

Retailers understand that securing cash and valuables requires more than just locking a door. Composite construction is the go-to for those who take security seriously.

🔨 Built for Real Threats

Concrete-filled steel walls resist cutting, drilling, and prying—unlike vulnerable drywall interiors.

🔐 Layered Digital Security

Features like multi-user access, audit logs, and time-delay locks work best when housed in a tamper-resistant composite shell.

🔥 Consistent Fire Protection

Composite cores hold up under prolonged heat, unlike drywall, which degrades into dust or steam-damaged debris.

🧰 Trusted Support & Longevity

Composite safes are more repairable and serviceable, often backed by warranty and maintenance plans.

🧭 Final Takeaway

Choosing a safe isn’t just about storing valuables—it’s about knowing your risk and selecting a product that’s built to meet it.

- Composite-built safes are engineered to stand up to heat, tools, time, and wear.

- Drywall-based safes might be cheaper, but when it counts, they often fall short.

💬 Ready for a Custom Recommendation?

Let us help you find the right safe, built to meet your exact needs

📞 Call us at (866) 747-7233

📧 Email: [email protected]

🌐 Explore solutions at bluedotsafes.com